A Selection of Internal Bikar Metal Asia Invoices, Delivery Notices, and Facsimiles

The International Nature of the Khan Network to Supplement Peddling Peril

April 2, 2010

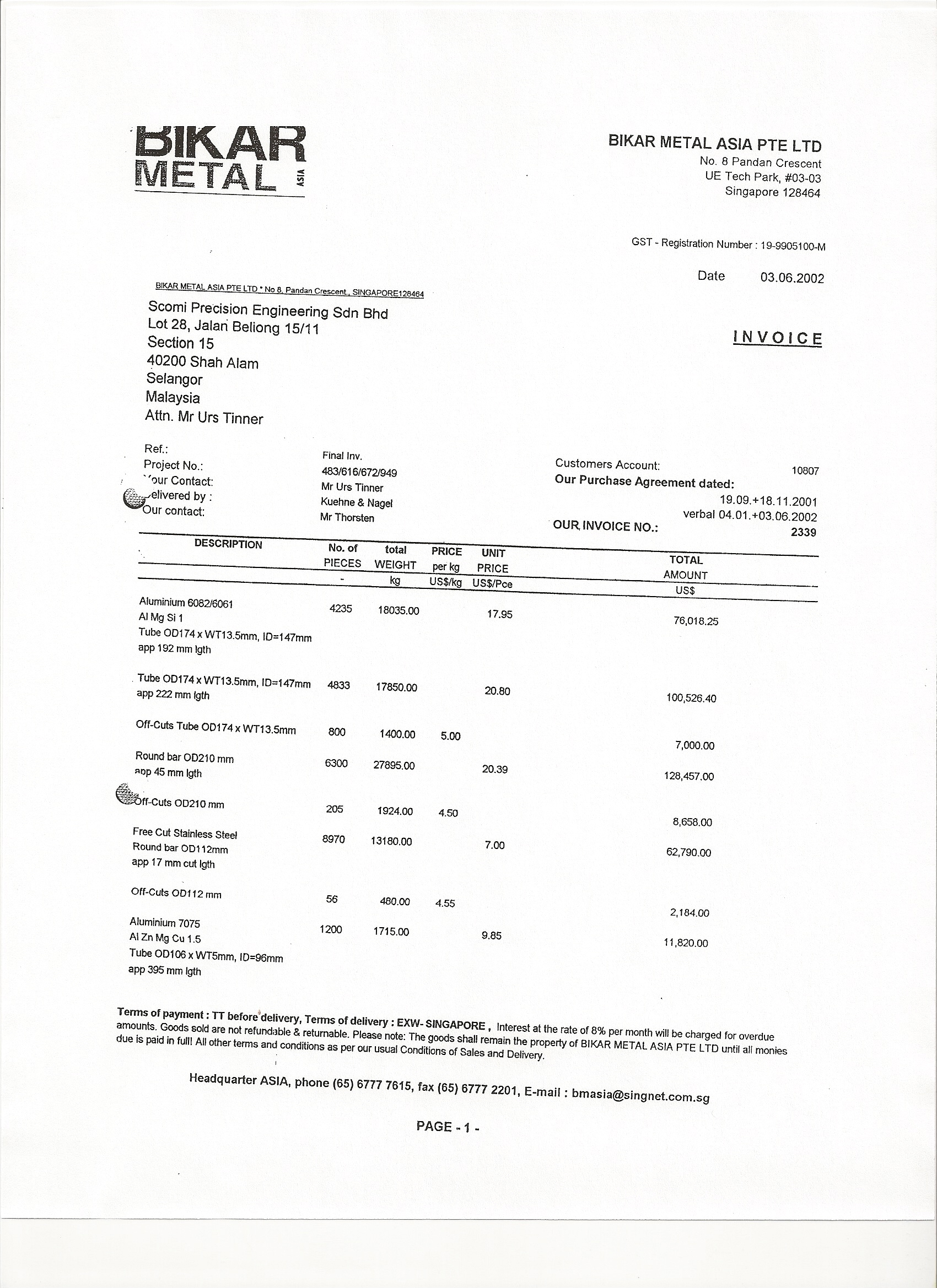

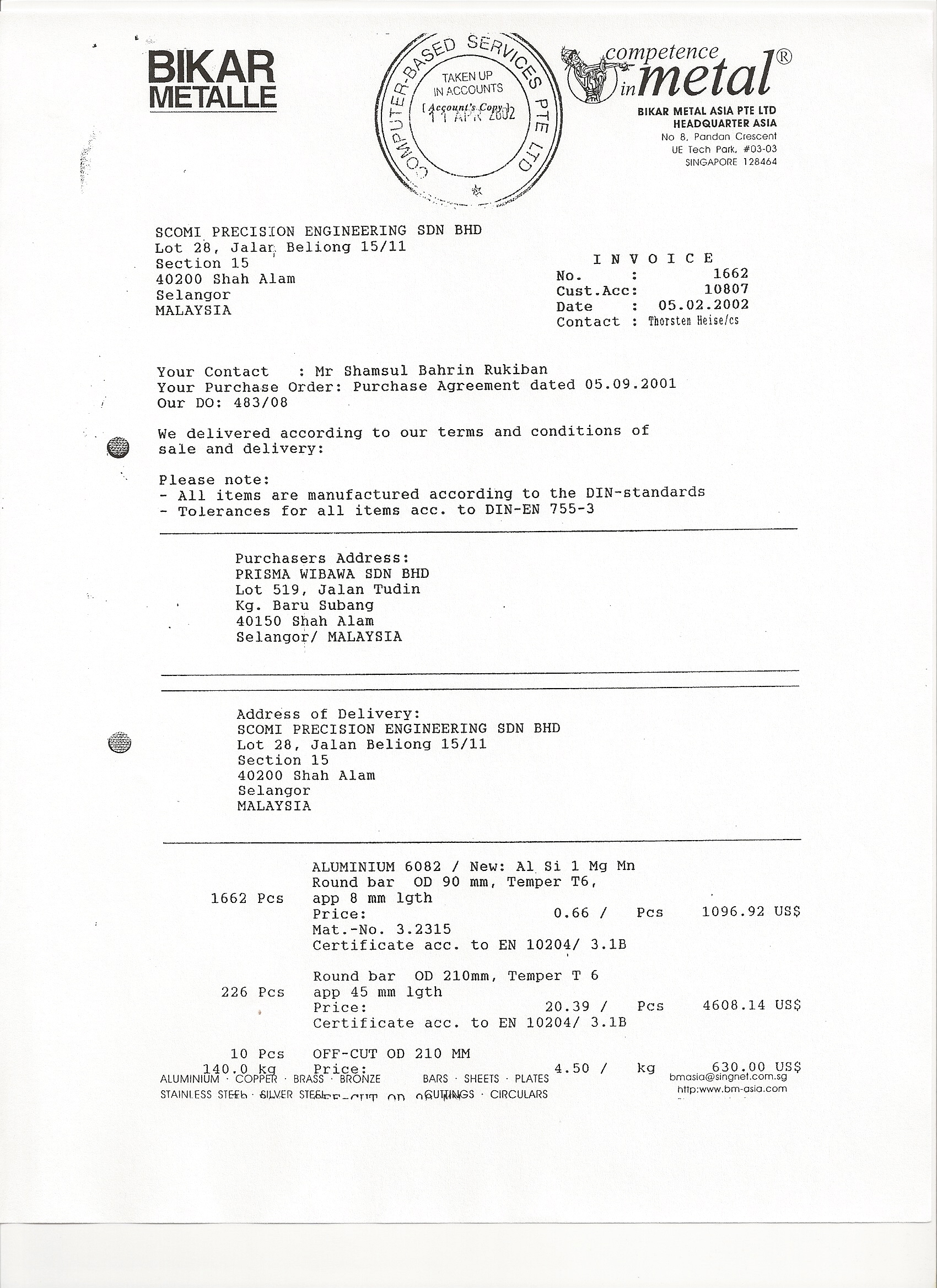

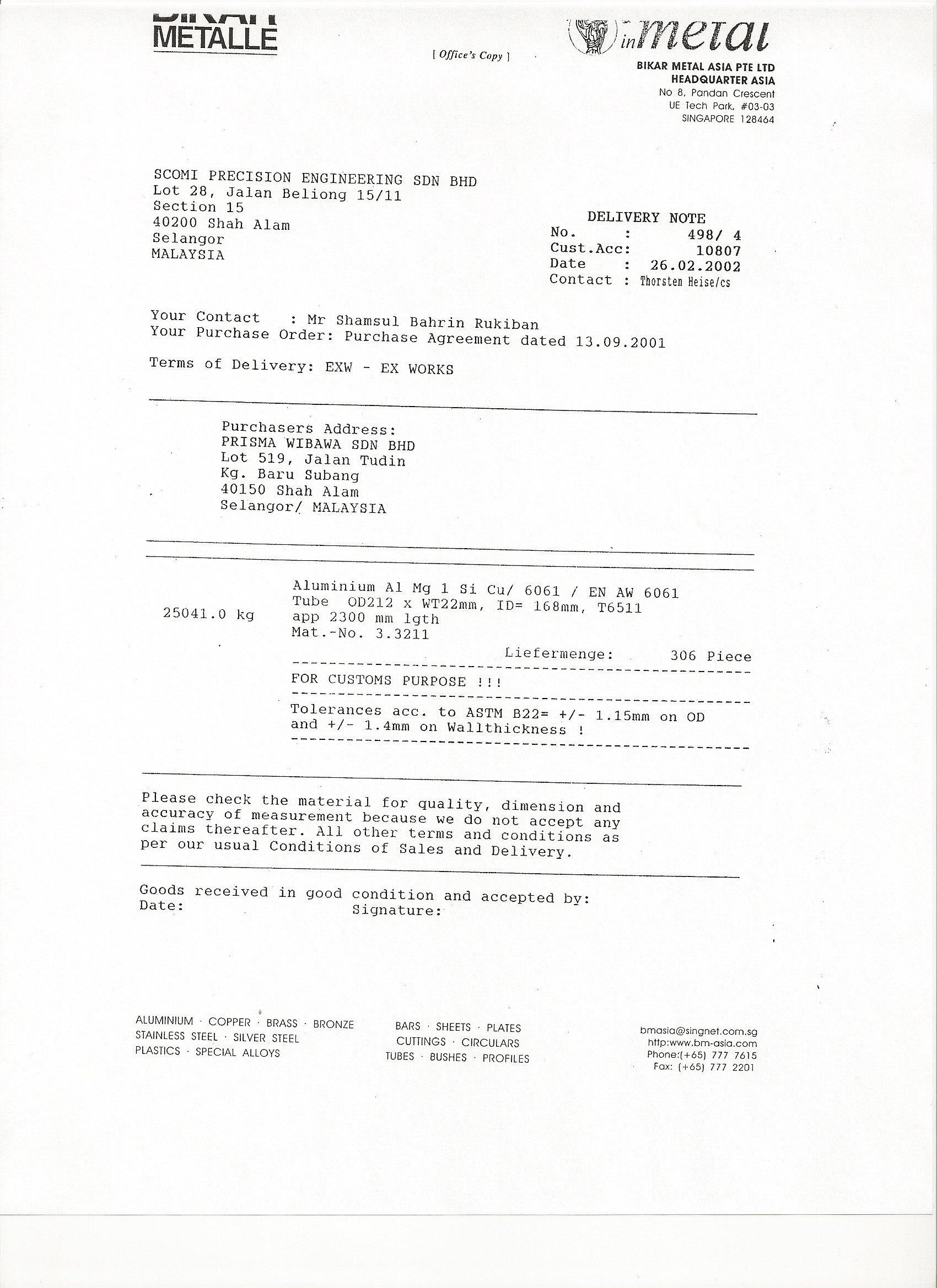

Chapter 6 of Peddling Peril discusses the Khan network’s supply of a gas centrifuge plant to Libya, detailing how the network organized the supply of hundreds of tonnes of raw aluminum for making centrifuge components in Malaysia and Switzerland. The aluminum was in the form of “preforms,” which are partially machined aluminum tubes or rods that are then inserted into computer numerically controlled machine tools for cutting into final shape. The individuals in charge of procurement included Urs Tinner of Switzerland and Shamsul Bahrin Rukiban of Malaysia; both were affiliated with Scomi Precision Engineering (SCOPE), and contracted with Bikar Metal Asia, based in Singapore, for the aluminum. Bikar Metal Asia, which is a daughter company of the German metal supplier Bikar Metalle GmbH, obtained the aluminum from several suppliers and brokers in Europe and Russia.

The following documents are a small sample from a set that numbers in the hundreds which ISIS obtained in 2004 and subsequently analyzed. These documents illustrate the international supply chain used by the Khan network, the ease with which it obtained these goods (some of which are on international nuclear-related dual use lists), the relatively open international communication used by the suppliers and purchasers, and the care exercised by Urs Tinner to ensure that the quality of the aluminum preforms was adequate to make centrifuge components.

This last point is relevant in evaluating when Urs Tinner started working for the CIA, which some reports date to as early as 2000 or 2001. In contrast, Swiss prosecutors date his formal relationship with the CIA to 2003; prior to that date he may have been a reluctant CIA source but was not engaged directly with an intelligence agency. Urs has stated that he falsified some centrifuge components, but his emphasis on quality control in March 2002 would suggest that he was at that time concerned about ensuring adequate quality of the centrifuge parts. He and his family were also at that time making considerable money manufacturing the components for Libya.

(click to enlarge)

(click to enlarge)

(click to enlarge)

(click to enlarge)

(click to enlarge)

(click to enlarge)

(click to enlarge)

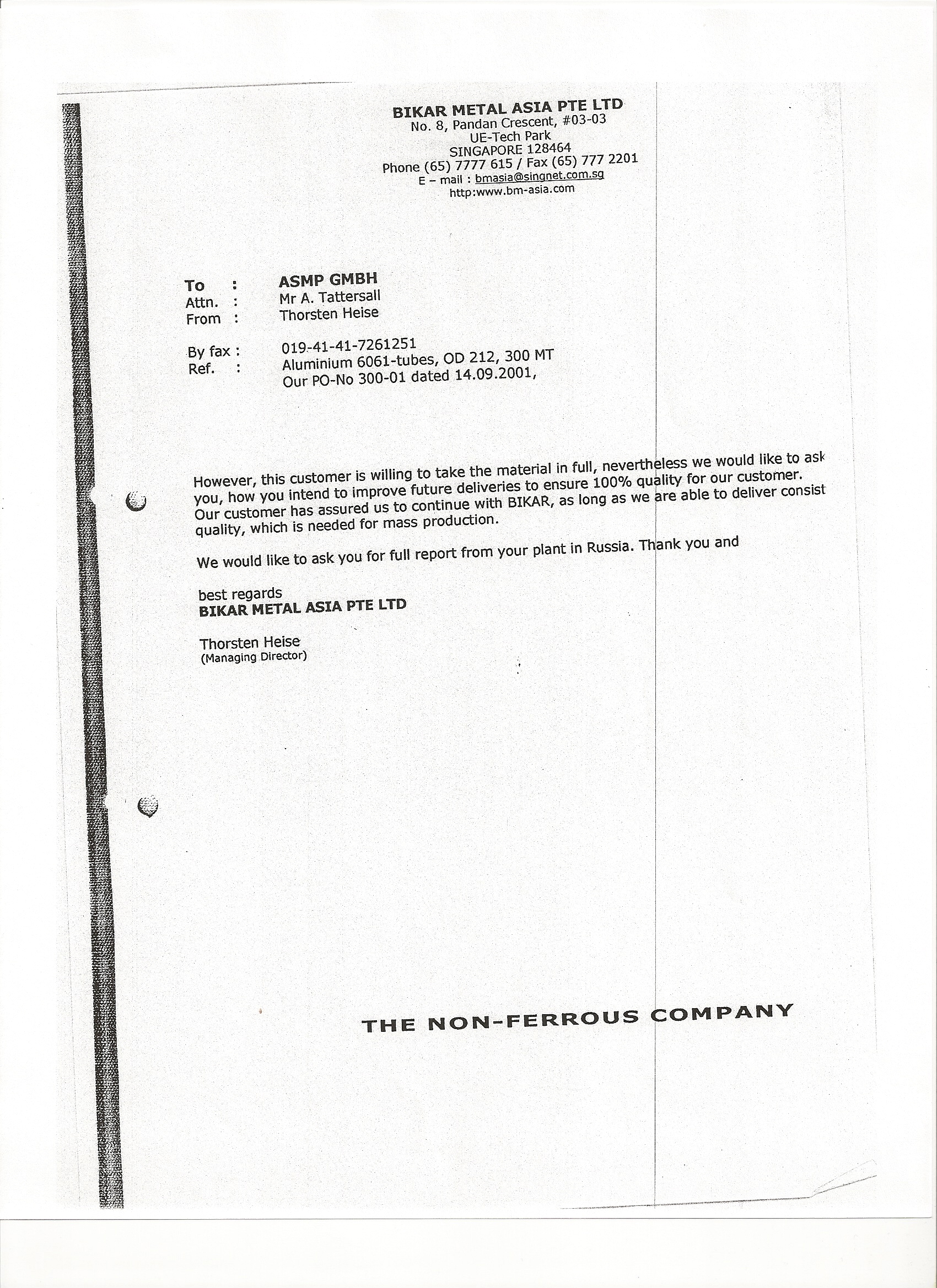

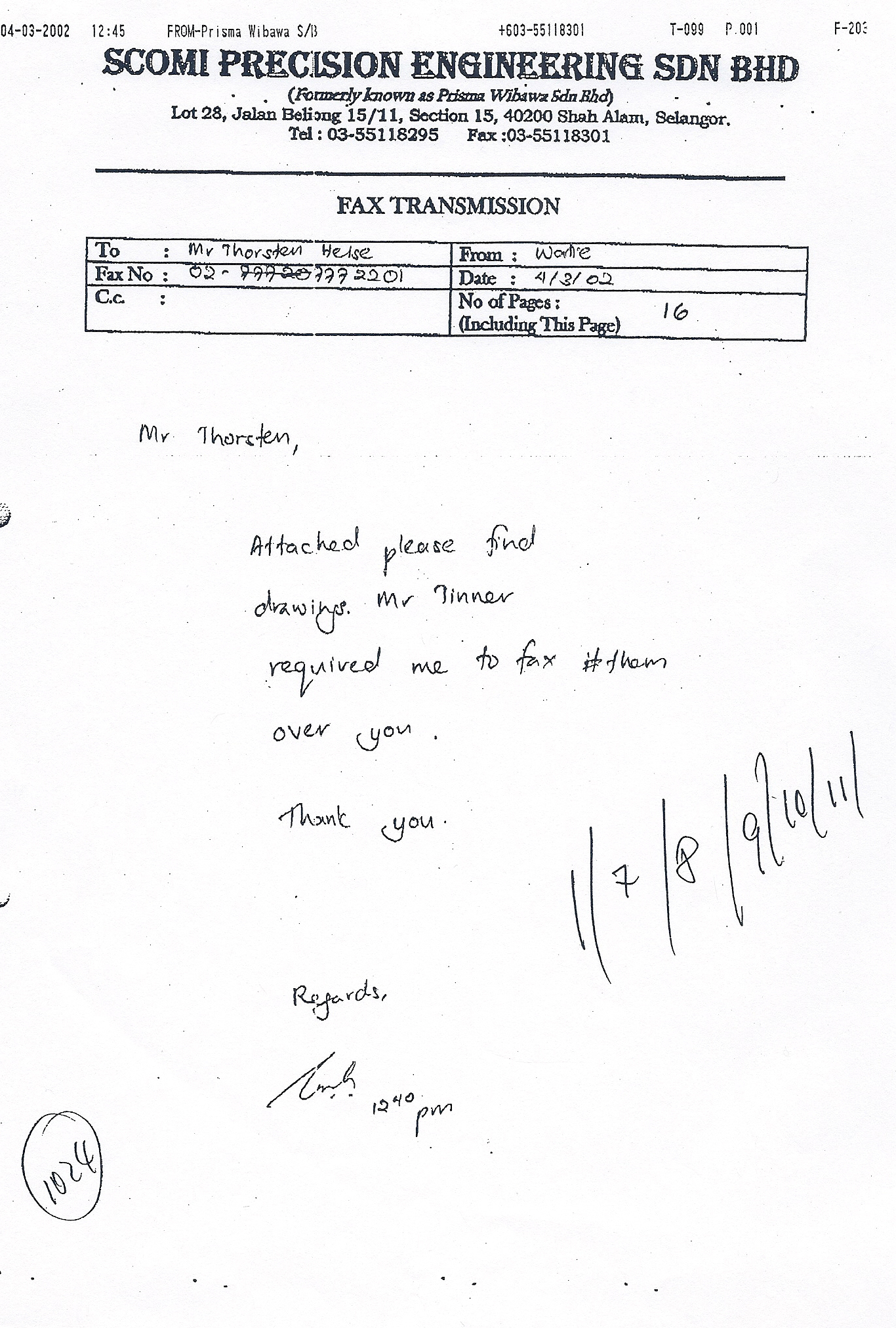

Document 6 and 7. Below is a two-page facsimile from Heise at Bikar Metal Asia to one of his aluminum brokers, ASMP in Switzerland, requesting a discount for the poor quality of about 20 percent of aluminum tube deliveries, where the aluminum originally came from a Russian company. This letter shows that SCOPE checked the quality of the aluminum preforms. This copy is missing the far right side of the original, which obscures the date, but associated documents give the date as early March 2002. The third document, an earlier facsimile, from SCOPE to Heise, is the cover sheet for 15 tube drawings that showed the poor quality of many of these tubes. This facsimile was sent to Heise at the request of Urs Tinner.

(click to enlarge)

(click to enlarge)

(click to enlarge)

‹ Back

News and Reviews

- The Best Books of the Year: Foreign Affairs Edition

- IEEE Review of Peddling Peril

- LA Times Book review: 'Peddling Peril'

- The New York Review of Books: Nukes for Sale

- The Tavis Smiley Show: David Albright Interviewed

- Economist review: Unstoppable?

- David Albright's Interview on NPR's Fresh Air

- David Albright on CNN's Situation Room with Wolf Blitzer

- Saddam Hussein weighed nuclear 'package' deal in 1990, documents show

Documents and Analysis

- Detecting and Disrupting Illicit Nuclear Trade after A.Q. Khan

- The Leybold Charter: Putting Non-Proliferation Above Commercial Interests

- Pakistani Government Seeks to Investigate A.Q. Khan’s Activities

- The Price of Getting Documents from A.Q. Khan: Carrying his Water

- Project AB: The Khan network's offer to Iraq regarding nuclear weapons

- P2 rotor assemblies delivered to Libya by the Khan network

- Excerpt of Peddling Peril published in Foreign Policy