- Home

- Iran’s new centrifuge: What do we know about it?

Reports

Iran’s new centrifuge: What do we know about it?

by David Albright, Jacqueline Shire, and Paul Brannan

April 13, 2010

Download PDF

Download PDF

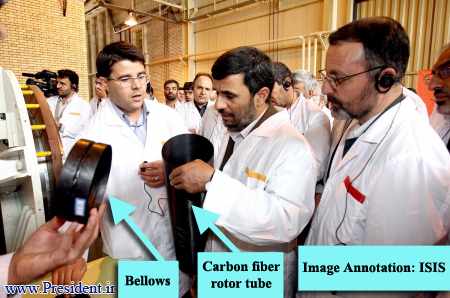

On Friday, April 9, Iran’s National Nuclear Technology day, President Ahmadinejad unveiled what he termed a “third generation” centrifuge (see photos in figure 1). Iran provided very little information about this machine – its potential performance, the number Iran has produced, the quantity it plans eventually to install, or when it would deploy any at Natanz or other enrichment facilities. The President also did not address the logical question of what became of Iran’s second generation centrifuge, particularly when or if it would be deployed as well.

Based on publicly available information, some limited conclusions can be drawn about the construction and potential operation of the centrifuge revealed on Nuclear Day. Video of the centrifuge taken by Iranian state news organizations can be found here.

<

ul>

Ali Akbar Salehi, head of the Atomic Energy Organization of Iran, has reportedly stated that the centrifuge has an enrichment output of 10 separative work units (swu) per machine per year 1. He said that the P1 centrifuge has an output of 1.8 swu per year per machine.

In a surprise announcement, given the prominence of the revelation, Salehi said that the third generation machine had not yet been tested with uranium hexafluoride (UF6), a fundamental step in establishing the viability and enrichment performance of the machine. Salehi stated that Iran would introduce uranium hexafluoride to the centrifuges within the next few months and that “We may need a year of time before we can arrange a cascade (of third-generation centrifuges) for testing.” 2 Salehi said that the centrifuge has undergone mechanical testing, which involves spinning the rotor assembly under vacuum. However, Iran’s mechanical testing procedures are unknown and are believed to be less strenuous than in the European centrifuge programs.

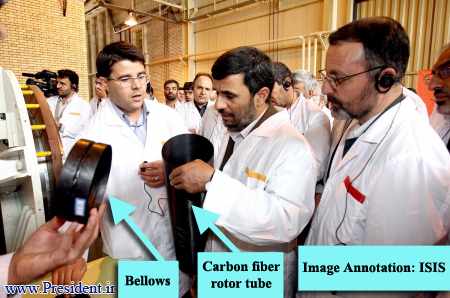

The centrifuge itself is somewhat longer than one meter and has a diameter over 20 centimeters. We assess it is constructed of two carbon fiber rotor tubes joined by a single bellows. The predecessor of the third generation centrifuge is the IR-2, which is a modified version of the P-2 centrifuge (Iran received the design drawings for the P-2 from A.Q. Khan in 1996 but did little with them until 2002 when an Iranian engineer set out to improve upon the crash-prone P-1). 3 The major modification in the IR-2 centrifuge is that it has a single rotor tube made from the more advanced material carbon fiber with a length of about 0.5-0.6 meters. The IR-2 does not have a bellows, since the Iranian engineer did not believe at the time that Iran was capable of building a P2-type bellows. That situation may have changed, as the third generation machine appears to be about twice the length of the IR-2 and has a bellows.

If Iran has managed to make this type of bellows for its third generation centrifuge, that would be a major accomplishment. Making this bellows is challenging technically, although this picture (figure 2) shows that Iran has been developing such a bellows for several years.

The IR-2 centrifuge has a nominal enrichment output of five swu per year, like the P2 centrifuge. Although the IR-2 machine is half the length of the P2 centrifuge, the rotor in the IR-2 can spin considerably faster than the steel P2 rotor assembly, raising the IR-2’s output to that of the P2 centrifuge. By doubling the length of the rotor assembly, Iran is theoretically capable of doubling the centrifuge’s output to 10 swu per year.

Figure 1. Several still images from a video of Iran’s unveiling of its “third generation” centrifuge.

Figure 1. Several still images from a video of Iran’s unveiling of its “third generation” centrifuge.

Figure 2. In the foreground is a bellows, which is probably oxidized or “blackened” maraging steel. Oxidation prevents corrosion by uranium hexafluoride.

Figure 2. In the foreground is a bellows, which is probably oxidized or “blackened” maraging steel. Oxidation prevents corrosion by uranium hexafluoride.

1 Iran to Mass-Produce 2nd Generation of Centrifuges, Fars News Agency, April 11, 2010: http://english.farsnews.com/newstext.php?nn=8901221161

2 Ibid.

3 David Albright, Peddling Peril, Free Press, New York, 2010, p. 97

twitter

twitter