Reports

Iran’s Advanced Centrifuges

by David Albright and Christina Walrond

October 19, 2011

Last summer, Iran began installing two cascades of advanced centrifuges at the Pilot Fuel Enrichment Plant (PFEP) at Natanz. As of August 28, 2011, according to the International Atomic Energy Agency (IAEA), Iran had installed 136 IR-2m centrifuges in cascade 5 and 27 IR-4 centrifuges in cascade 4. Iran started feeding 54 of the 136 IR-2m centrifuges with natural uranium hexafluoride.1 Each of these cascades is designed to contain 164 centrifuges. Iran first told the IAEA in January 2011 that it intended to install these two cascades, and it is unclear why Iran waited nearly eight months before starting to install them.

<

p> Installation of the IR-2m centrifuges is now complete. Installation of the IR-4 centrifuges could finish anytime.

<

p> The purpose of operating these cascades at the PFEP is to demonstrate their performance prior to installation of production cascades at the Natanz plant, the Fordow facility, or possibly a third enrichment site that may currently be under construction. Iran should be able to finish this demonstration work at the pilot plant within six to nine months, and perhaps sooner.

<

p> Characteristics of IR-2m and IR-4 Centrifuges

<

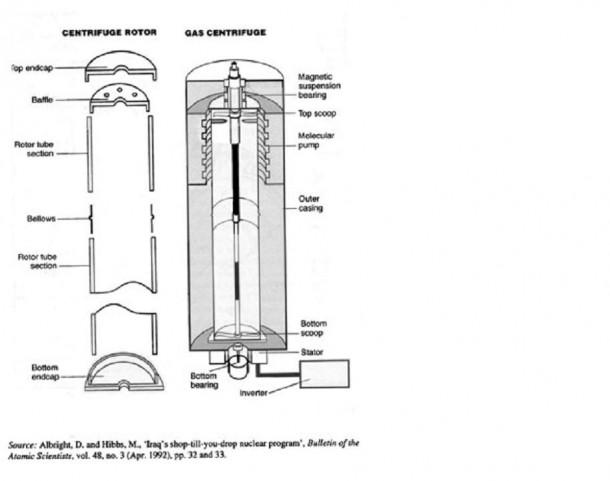

p> The IR-2m and the IR-4 centrifuges have the same length and diameter. They are derived from the Pakistani P2 centrifuge design that A.Q. Khan sold Iran in the 1990s. Iran subsequently modified this design (see figures 1 and 2). The IR-2m rotor is made of two carbon fiber rotor sections or tubes and a maraging steel bellows. The IR-4 has two carbon fiber tubes connected by a carbon fiber bellows, an unusual choice likely reflecting a shortage of maraging steel. Both centrifuge designs use a top and bottom bearing and a motor taken from the P2 design.

<

p> Khan found that the P2 design worked considerably better than the P1 centrifuge, suffering far fewer failures. Similarly, the IR-2m and IR-4 centrifuges are expected to have fewer breakdowns than the IR-1 centrifuges currently at the Natanz Fuel Enrichment Plant that are copies of the P1 centrifuge. However, as is discussed below, these centrifuges may not perform as expected.

<

p>

<

p>

<

p> Both the IR-2m and the IR-4 centrifuges are designed to have roughly the same enrichment output, about five separative work units (swu) per year per machine. Based on the inefficiencies expected in cascades and potential problems that Iran may yet encounter as it seeks to deploy these centrifuges, ISIS conservatively assesses that the average enrichment output of these centrifuges would be closer to 3-4 swu per year per centrifuge when operating in production cascades.

<

p> But this output is considerably greater than the output of the IR-1 centrifuges at Natanz. Currently, the IR-1 centrifuges in the Fuel Enrichment Plant (FEP) have an average of only about 0.75 swu per year per centrifuge, down from about 0.9 swu per year per centrifuge about a year ago (see ISIS’s analysis of the latest safeguards report on Iran here). So, the IR-2m and IR-4 centrifuges are projected to have an output that is about 4-5 times greater than the current output of the IR-1 centrifuges at the FEP. Thus, one thousand advanced centrifuges would be equivalent to about 4,000-5,000 IR-1 centrifuges, operating at values achieved currently at the FEP.

<

p> Why a Carbon Fiber Bellows?

<

p> Pakistan used maraging steel bellows in its P2 machines. But building a maraging steel bellows for a P2-type centrifuge is fraught with potential problems, and Iran has worked on manufacturing such a bellows for many years. The original version of the IR-2 centrifuge design consisted of only one rotor tube and no bellows, as Iran told the IAEA that it was unable to manufacture a P2-type maraging steel bellows at that time. However, this type of bellows is generally viewed as easier to make than developing and manufacturing a carbon fiber bellows.

<

p> Iran may have decided to build a carbon fiber bellows because of a shortage of maraging steel suitable for fabrication into a bellows. Iran likely is unable to produce adequate maraging steel tubes suitable for manufacture into bellows and sanctions have complicated Iran’s ability to purchase more abroad.

<

p> Iran’s on-going development work on centrifuges that do not use any maraging steel reinforces the assessment that it faces a shortage of maraging steel. For example, rotor assemblies typically have maraging steel top and bottom caps. Iran is trying to replace maraging steel end caps with high strength aluminum end caps. Aluminum is weaker than maraging steel, so this substitution does not make technical sense unless maraging steel is in short supply.

<

p> But building a reliable carbon fiber bellows may pose technical challenges that increase the risk of centrifuge failure. Thus, sanctions may have forced Iran into choosing a less desirable technical centrifuge design.

<

p>

Carbon Fiber is Difficult to Obtain As Well

<

p> Iran has failed on numerous occasions to buy high quality carbon fiber abroad. Such purchases by Iran violate sanctions, and states have exerted considerable effort in detecting and thwarting Iranian efforts to obtain carbon fiber in recent years.

<

p> In a seeming response to sanctions, in late August 2011, Iran announced that it had begun to domestically produce its own carbon fiber. However, this carbon fiber is judged to be of relatively poor quality and not adequate for gas centrifuge rotors. Iran is assessed as still being dependent on illicit procurement of carbon fiber from abroad for its centrifuge program.

<

p> One key unknown is the quality and quantity of carbon fiber Iran acquired overseas prior to the marked increase in sanctions, particularly following the imposition of United Nations Security Council resolutions on Iran starting five years ago. Prior to these harsher sanctions, Iran had an easier time smuggling controlled goods to its nuclear program. After its P2-type centrifuge development program was exposed in 2004, Iran told the IAEA that it had stopped procurement of any goods for its P2-type program. These procurements appear to have aimed to acquire enough raw materials for several thousand P2-type centrifuges that utilized a single carbon fiber rotor. However, Iran may have not cancelled all its orders, and the IAEA reportedly has suspicions that this is indeed the case. Thus, uncertainty surrounds estimates of Iran’s stock of high quality carbon fiber. It may have on hand enough carbon fiber for a few thousand advanced centrifuges, where two rotor tubes are needed for each centrifuge. It is doubtful, however, that Iran has enough fiber to build thousands of IR-2m or IR-4 centrifuges.

<

p> Yet because of the potential enrichment output of the advanced centrifuges a stocklarge enough for a few thousand advanced centrifuges raises serious concerns. With 1,000 IR-2m or IR-4 centrifuges, Iran could break out and produce enough weapon-grade uranium for a nuclear weapon using a stock of low enriched uranium relatively rapidly. Moreover, if Iran successfully develops these centrifuges at the PFEP, it could manufacture this number over several months, assuming it has enough raw materials. Installation could start next year at Fordow or at a potentially secret enrichment site. Furthermore, a secret enrichment facility containing this number of advanced machines would be considerably smaller than the Fordow facility and more difficult to locate.

<

p> Findings

<

p> Starting in 2012, Iran seems poised to install up to a thousand advanced centrifuges. Several factors, however, may undermine this schedule. In addition, more attention to implementing sanctions could inhibit Iran’s ability to dramatically increase this number and to obtain goods to replace broken centrifuges. An Iranian inability to reliably procure necessary raw materials in support of an on-going advanced centrifuge program could impact the extent to which Iran would incorporate a finite number of machines into its uranium enrichment program. Iran may hesitate to deploy large numbers of these machines if it cannot reliably re-supply them.

<

p> A shortage of maraging steel could limit the number of IR-2m centrifuges Iran could make. This shortage could require Iran to depend on the IR-4 centrifuge, so its successful development could be critical to Iran’s ability to deploy production centrifuge cascades.

<

p> Sanctions may have forced Iran to move away from the relatively easier-to-make maraging steel bellows to depending on carbon fiber bellows. Due to possible technical challenges that could accompany producing bellows out of carbon fiber, Iran may have difficulty producing effective IR-4 centrifuges, causing additional delays in their deployment. In the coming months, Iran’s progress on the IR-4 should be visible at the Natanz pilot enrichment plant, allowing for a better judgment of the reliability of this design.

<

p> These same sanctions could complicate or delay Iran’s ability to build large numbers of these advanced centrifuges. Iran may not be able to acquire enough high quality carbon fiber and other goods for them. Responsible countries and suppliers should increase their vigilance against Iranian smuggling operations aimed at procuring for Iran’s nuclear programs.

<

p> Constraints on Iran’s advanced centrifuge program have resulted directly from the effectiveness of targeted sanctions against critical goods necessary for the manufacture of centrifuge components. However, since 1,000 advanced centrifuges could effectively match the current enrichment output of the FEP at Natanz, it is imperative that sanctions and related enforcement actions are implemented more effectively to further limit Iran’s ability to advance its centrifuge program. To do so, targeted sanctions on carbon fiber are a priority, and the international community should work diligently to stymie Iran’s future procurement efforts.

<

p> Ultimately, though, sanctions and other measures may only slow the pace at which Iran can procure what it needs to support its uranium enrichment program. The international community still needs to find a solution that settles the dispute over the Iran nuclear issue while resolving concerns regarding the military dimensions of its program.

<

p>

<

p>

1 The advanced centrifuge cascades at the PFEP do not discharge enriched uranium; after enriching uranium, this product is recombined with the waste or tails, resulting in natural uranium.

<

p>

twitter

twitter